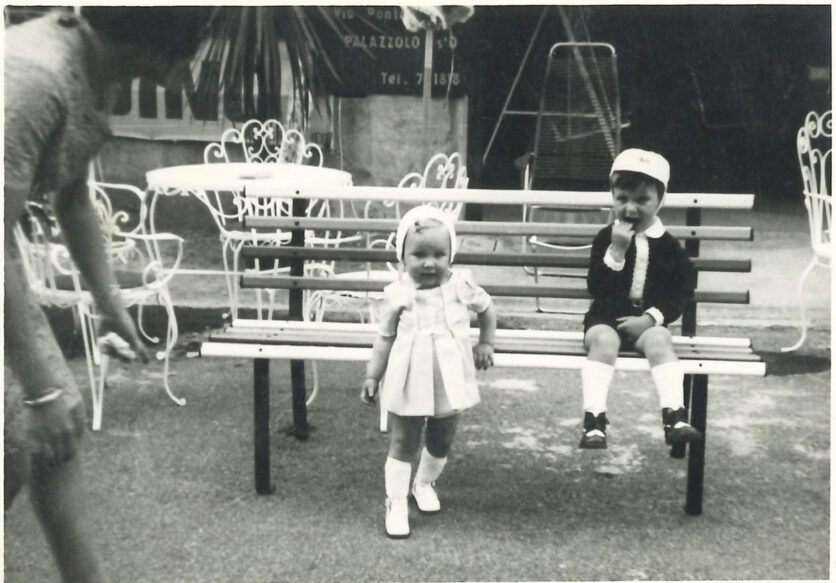

LUCA MOLINARI RETRACES ITS HISTORY WITH MONICA PEDRALI, SECOND GENERATION AND CEO PEDRALI, TOGETHER WITH HER BROTHER GIUSEPPE.

Luca Molinari | Pedrali celebrates its first sixty years of activity thanks to the work and initiative of its founder, Mario Pedrali, and the last three decades of work thanks to you and your brother Giuseppe. What do you consider to be the fundamental and enduring characteristics of your company?

Monica Pedrali | Over the years Pedrali’s enduring characteristics have been the ability to update the factory while maintaining 100% Italian production, the opening up to new sectors and markets through significant innovations while still remaining true to our roots and constantly aiming for qualitative growth, before quantitative. Furthermore, at Pedrali we welcome young people and teach them skills, something which has been made possible thanks to the generosity of those people who have passed down their own knowledge to new generations. Mario is a good example of this: he was extremely generous in making space for Giuseppe and I when we joined the company. Another distinguishing feature that sets Pedrali apart in the panorama of design furniture is its ability to find its place in different sectors, creating in each of these relationships of trust with customers who, for decades, have continued to buy from us. Mario’s cutting-edge vision has always been to promote the brand identity. Initially, he did this at a local level with trade fairs and local sponsorships, then in the 1980s and 1990s he expanded to include international trade shows and later the Salone del Mobile, the most important trade show in the world for our sector, which represents a moment of pure happiness. It is an opportunity to meet people, to compare oneself with others, to see the results of the work done in the previous year, and it gives a genuine sense of satisfaction. I believe that Pedrali is beauty, tradition and innovation but first and foremost a community: a group of people who enthusiastically and diligently pursue a common goal of producing quality furniture that endures over time and gives a sense of beauty to the places we live in.

L.M. | How would you describe the company’s growth, its organization, and its history?

M.P. | Mario has always been a creative person and he’s had many ideas that have proved over time to be both interesting and ingenious. When Giuseppe and I joined the company, we started collaborating with designers, which allowed us to experiment and experience beyond the confines of the company and this led us to increasingly ambitious challenges in the development and production of products, designed to be both innovative and durable. What’s more, through exchanging information with our research and development office, some fabulous ideas have emerged from a production and engineering perspective. It is from discussion that we realised how much the sustainability of a product can be defined already at the design phase. Decisions like choosing the right materials for a product, which technologies to use, and which packaging, as well as the disassemblability of the product itself, all make a significant difference. When we began producing wooden furniture at our Manzano division, we encouraged the designers to use as little raw material as possible and thus to preserve this precious material through thoughtful use. Over the years we have experimented with the use of different materials, even in combination with each other, leading to several changes that allow us to produce wood, metal, upholstered and woven furniture today. Sustainability is an essential characteristic, one of our cornerstones. For our wooden products, we decided to use only wood sourced from responsibly managed forests— products that are FSC ® C114358 certified. We adopted water-based coatings, composed mostly of plant-derived resins and we also created in 2020 the first chairs made from recycled polypropylene: 50% from post-consumer waste and 50% from industrial waste. In 2018, we started the Corporate Carbon Footprint study and in 2019 we obtained certification according to UNI EN ISO 14064-1:2019. In addition, we continue to focus on occupational safety and social responsibility, and this will continue to be our constant direction. Furthermore, our production, in order to reduce waste of raw materials, is based on a just-in-time approach and this has led us to develop customised products, producing exactly what is needed and meeting the demands of architects and interior designers. As a result, we’ve made a significant leap in quality, shifting from selling products to creating projects. This too has brought us great satisfaction.

L.M. | One of the most significant contributions you made to Pedrali was increasing the company’s internationalization and expanding into new markets. Could you explain the reason and thinking behind this choice?

M.P. | In terms of internationalization, I really must thank Mario, who was responsible for instilling in me the passion for travel and cultures that lead to confrontation and encounters. When I joined the company, my task was to develop emerging markets, and to do so, we needed to have products with international appeal, a democratic product. It was also essential to have production capabilities and well organized logistics, but most importantly, people able to convey Italian culture and craftsmanship, strengthening the perception of “Made in Italy” worldwide. Because of this, I surrounded myself with people who formed a true team: agents, retailers and later on the relationships established with Michelin-starred chefs, as well as with investors in large office and hotel projects. This made Pedrali the link between designers, investors, factory and product designer. Today, Pedrali exports to over 100 countries. This was made possible by having an efficient manufacturing and production capabilities, an organized logistics system and most importantly, a commercial team—both internal and external— who is ambassador for Italian culture worldwide, even before promoting Pedrali. The challenge for the future is to be prepared for increasingly rapid changes and to manage an increasingly complex market.

L.M. | So, how would you describe “Made in Italy” today?

M.P. | “Made in Italy” is something that cannot be found anywhere else in the world. In our territory, there is a culture of beauty, art, and the idea of bringing all this into everyday life. We also have a vast amount of technical expertise, machinery

and creativity, all of which makes us unique. However, “Made in Italy” does not only mean using the cutting-edge technologies we have in Italy, interconnected machinery or digitalization, it also means that unique Italian craftsmanship and knowhow which still involve a lot of manual work. It is essential for future generations to be able to pass on Italian know-how and craftsmanship and safeguard all the expertise of our territory.

L.M. | Pedrali has always acted as part of a broader community, not least in terms of taking part in cultural and educational projects in the region. Could you tell us a little more about this?

M.P. | One of Pedrali’s hallmarks has been the creation of an organization capable of involving young people, teaching them skills while working alongside more experienced individuals and instilling in them a passion for the furniture sector. So, even though the company has interconnected machinery and a vast amount of digitalization, there is still a need for craftsmanship and the added value brought by people, who, day after day, make this industry recognisable all over the world. For several years now, we have been involved in initiatives such as “#Pedrali4art”, “#Pedrali4culture” and “#Pedrali4education” which allow us to connect with universities and schools in order to show young students that Italian craftsmanship is essential and that the furniture sector is one of the most important for both our country and our economy. During the year of Bergamo and Brescia Capital of Culture 2023 we have intensified our connections and partnerships with museums and cultural associations in the area. I must say that we are learning a lot from these collaborations.

L.M. | What are your desires for Pedrali in the next sixty years?

M.P. | For the next sixty years, we want to keep productio in Italy and continue to focus on sustainability and our environmental approach. However, the challenges for the future are to transmit the heritage of Italian craftsmanship to young people and to see the factory as a Hub where different generations and experiences can come together. I like to think of the Pedrali Pavilion, designed by AMDL CIRCLE and Michele de Lucchi, as a meeting point, where relationships can be forged, where teamwork can take place, where empathy and serenity can truly create a stimulating place to work and where new, beautiful ideas can come to life. As Mario says, “If we surround ourselves with beautiful people, beautiful things happen. We will continue to put people at the heart of our work.