For some years now, gres porcelain has certainly been the most widely used material for floor and wall coverings, due to its outstanding technical characteristics. Increasingly larger formats, reduced thicknesses and a lower water absorption coefficient of < 0.5%, also challenge manufacturers of tile adhesive. How to cope with modern stoneware tiles which are practically a non- absorbent product?

With the help of chemistry, modern thinset adhesives offer extremely high bonding performance as a solution to fix gres porcelain to the substrate. But that literally means welding together two different materials with unequal expansion coefficients, thus creating important shear-stress between the two elements. Cracking and/or detachment of tiles have therefore become an increasingly frequent issue and even using so-called “flexible” adhesives (marked with an S”) did not eliminate this inconvenience. As early as 1987, Werner Schlüter, a German master tile layer, invented the DITRA membrane, and introduced the idea of bonded uncoupling, revolutionizing the hitherto known concept of rigid adhesive laying. DITRA is produced in polypropylene, and thanks to this material choice and to its special hollow dovetail geometry, it “separates” the gres porcelain tiles from the substrate while still guaranteeing proper adhesion.

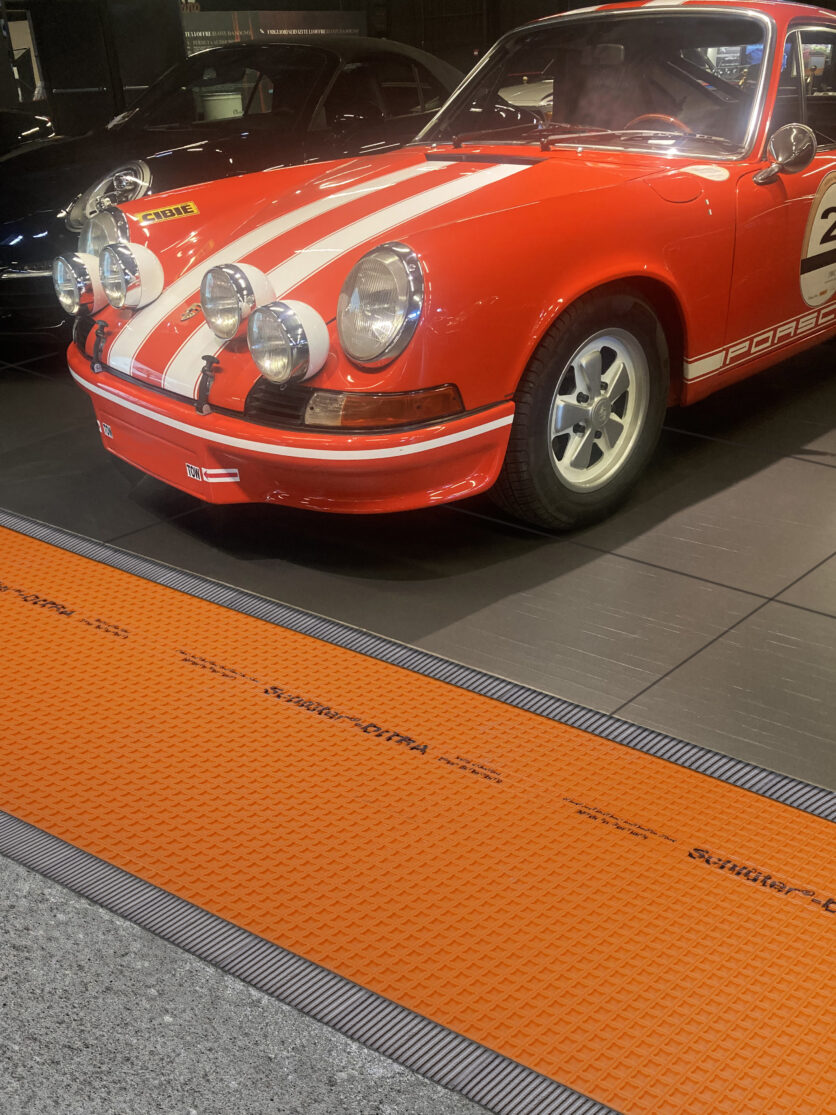

Schlüter-Systems, the inventor of bonded uncoupling membranes, offers complete guarantees and certifications for all its systems.